I twined the deer sinew thread used to sew this knife sheath using a two strand reverse twist method. The gorgeous fish skin, deer rawhide and sinew I used to make the sheath were harvested and processed on Kodiak Island by C. Chernoff.

How does one process fish skin? First, you need a fisherman – or fishergirl! This is my granddaughter – she caught the spawned-out salmon for me on the board below.

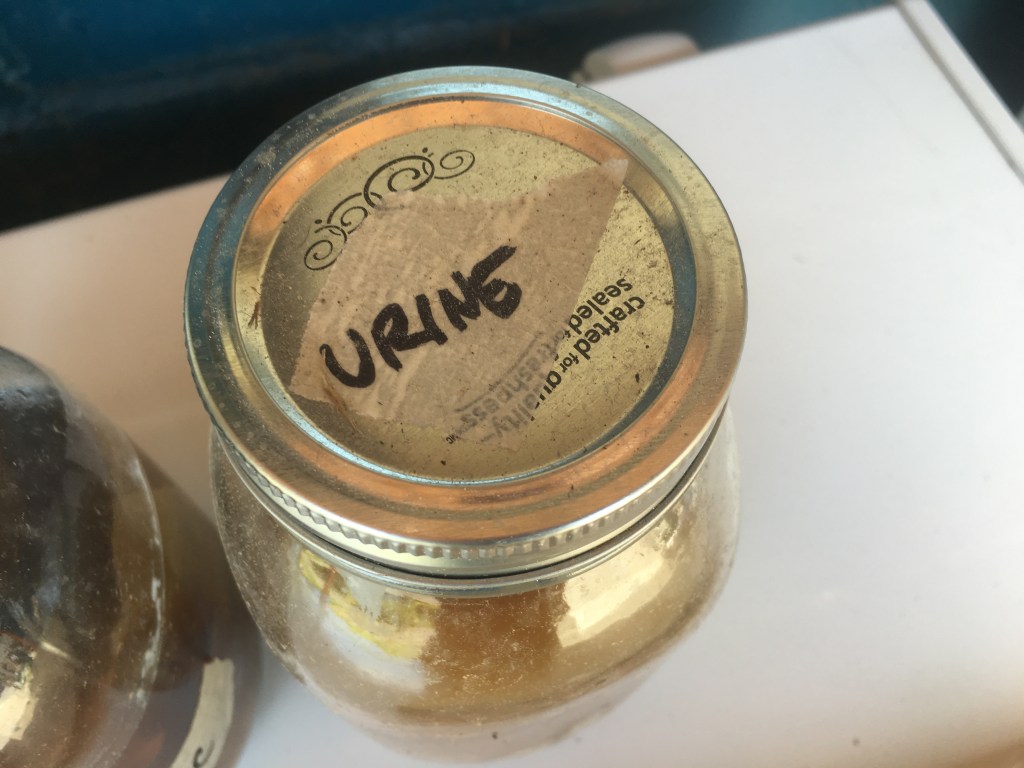

After you have the skin, you scrape off the meat on the inside if the skin and place it in a canning jar with urine. I have left skins soaking for up to 9 months without issue.

My husband has always generously provided his urine but in researching the process I read that on Kodiak Island prepubescent male urine was favored.

Then, weeks to months later… I take the jars outside and work each skin with egg yolk. I rinse the skins and have found that the scales come right off if you soak the skins for many months. Then I dip the damp skin in yolk and work it until my hands are tired and the yolk is thick and dry. I usually move on to another skin and work to soften the pile of dry skins later just like you would an animal hide.

The outstanding properties of fish skin include the fact it has no orientation and easily compares to Tyvek. Shoes and other objects that need to be durable were often made of fish skin by Alaska Native people.

King salmon skins are especially beautiful when processed correctly. Many Alaska Native artists have secret processing methods – some more chemically inclusive than others. My goal is to utilize the easiest least noxious method to achieve my preferred feel and texture. I have tried raw whipped deer brain and salmon roe but like the simplicity and outcome of egg yolk the best.

© 2016 Jill HH Lipka. All rights reserved.

Updated version © 2023 Jill HH Lipka. All rights reserved.